Functionally Graded Hard Metals

Functionally Graded Hardmetals (WC-Co)

Comprehensive and systematic research has led to the development of a patented process that produces WC-Co with graded Co compositions via a simple heat treating process without significantly increasing manufacturing costs. The new process is now licensed to Heavystone Lab LLC, a start up company founded by the University of Utah Research Foundation and Professor Fang for the purpose of commercializing the technology (http://heavystonelab.com). These materials provide a hard, wear resistant surface with a tough core, thus extending tool life and reducing maintenance costs. WC-Co materials are an integral and critical component in metal working, and as tools for oil and gas drilling operations worldwide.

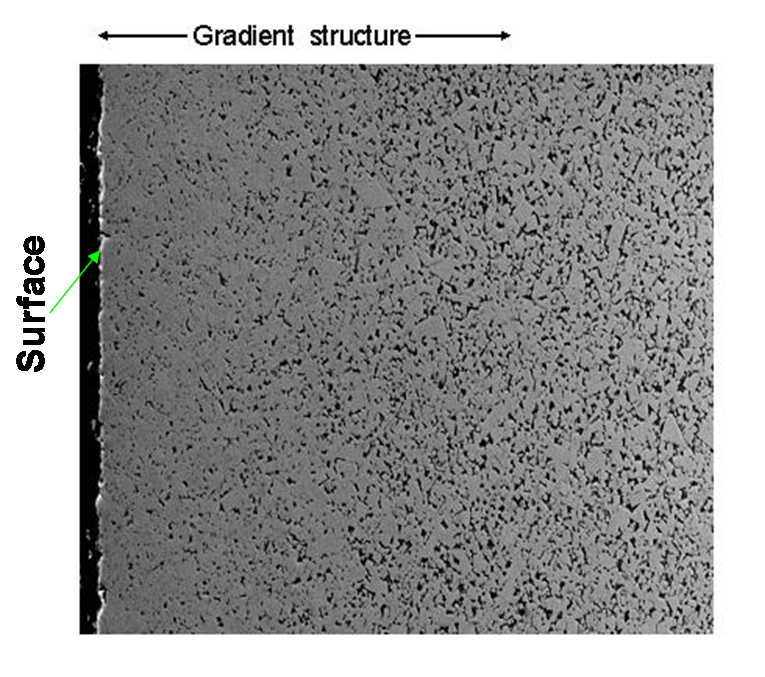

A novel carburizing treatment process has been developed for creating cobalt gradients in the near-surface regions of fully consolidated WC-Co parts. The higher WC concentrations at the surface result in a harder and more wear resistant component, while maintaining the fracture toughness of the interior of the processed tool or component. This technology can be performed in a sintering cycle or as a separate post-sintering treatment. Figure 1 shows a denser microstructure with higher WC concentration (light grey particles) in the surface region with a gradual increase in Co (black phase) toward the interior of a sample of FG WC-Co.

Fig 1. SEM micrograph of the polished cross-section of an FG WC-Co sample showing the graded microstructure by the gradual increase in Co (black phase) toward the interior of the sample.

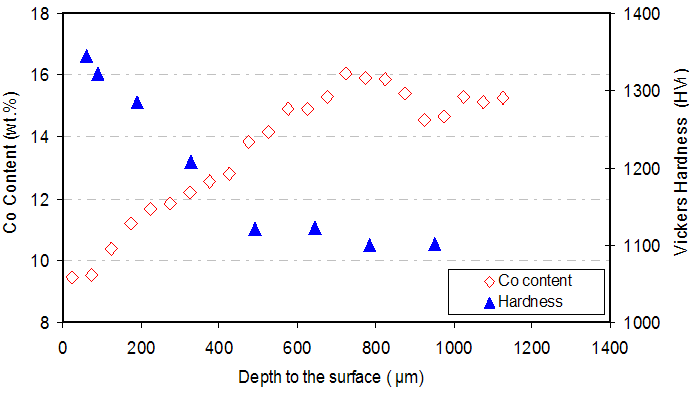

Gradient profiles of Co content and hardness in a sample of FG WC-Co with 16 wt% Co (FG WC-16Co) are presented in Fig. 2. The cobalt content increased gradually from ~9% at the surface to a peak value of 16%, leveling off at the nominal Co content in the bulk. The hardness value of the conventional 16 wt% Co material was measured at a Vicker's hardness of HV1 1052, and after the carburizing treatment the hardness at the surface was increased to HV1 1344, an increase of 28%. Thus, in the FG WC-Co samples studied, the highest hardness was measured at the surface where it is required to benefit wear properties. Compared with conventional cemented WC-Co, functionally graded WC-Co with a lower Co content in the surface region offers a superior combination of wear resistance and toughness, and these materials hold significant promise for a broad range of industrial applications from metal forming to tools for oil and gas drilling.

Fig 2. Co composition and hardness profiles vs. depth from the surface into the sample for FG WC-16Co, showing a constant gradient of increasing Co composition and decreasing hardness from the surface into the bulk of the sample.

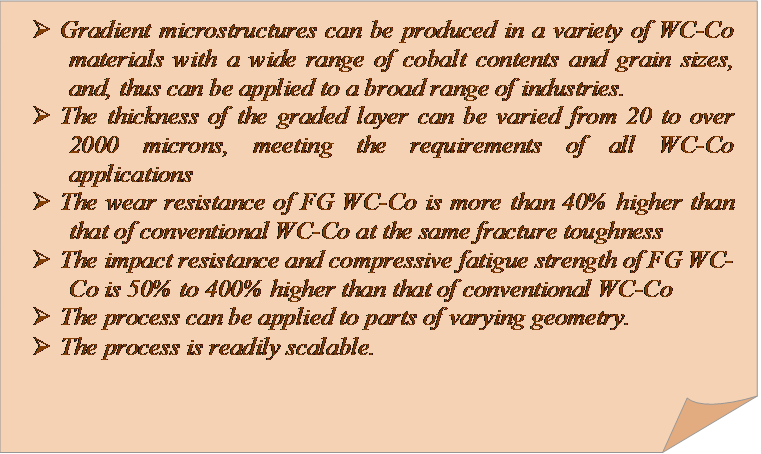

Compared to other methods for obtaining a graded WC-Co structure at the surface this process combines a number of advantages:

Reference

- Patents: US 8163232; EP2350331

- Xu Wang, Kyu Sup Hwang, Mark Koopman, and Z. Zak Fang, “Mechanical Properties and Wear Resistance of Functionally Graded WC-Co”, Int. J. of Refractory Metals and Hard Materials, In Press, Corrected Proof, Available online 19 April 2012.

- Jun Guo, Peng Fan, Xu Wang, and Z. Zak Fang. “A novel approach for manufacturing functionally graded cemented tungsten carbide". International Journal of Powder Metallurgy”, 2011, 47(3), P 55-62.

- Peng Fan, Z. Zak Fang and Jun Guo, “Liquid Phase Migration and Methods for Fabrication of Functionally Graded Cemented Tungsten Carbide”, Int. J. of Refractory Metals and Hard Materials, In Press, Corrected Proof, Available online 25 February 2012.

- Jun Guo, Z. Zak Fang, Peng Fan, and Xu Wang, “Kinetics of the Formation of Metal Binder Gradient in WC-Co by Carbon Diffusion Induced Liquid Migration”, Acta Materialia, 2011, 59, p.4719-4731.