Facilities and Equipment

Processing Equipment

Deoxygenation and Reduction Furnace

Analytical Equipment

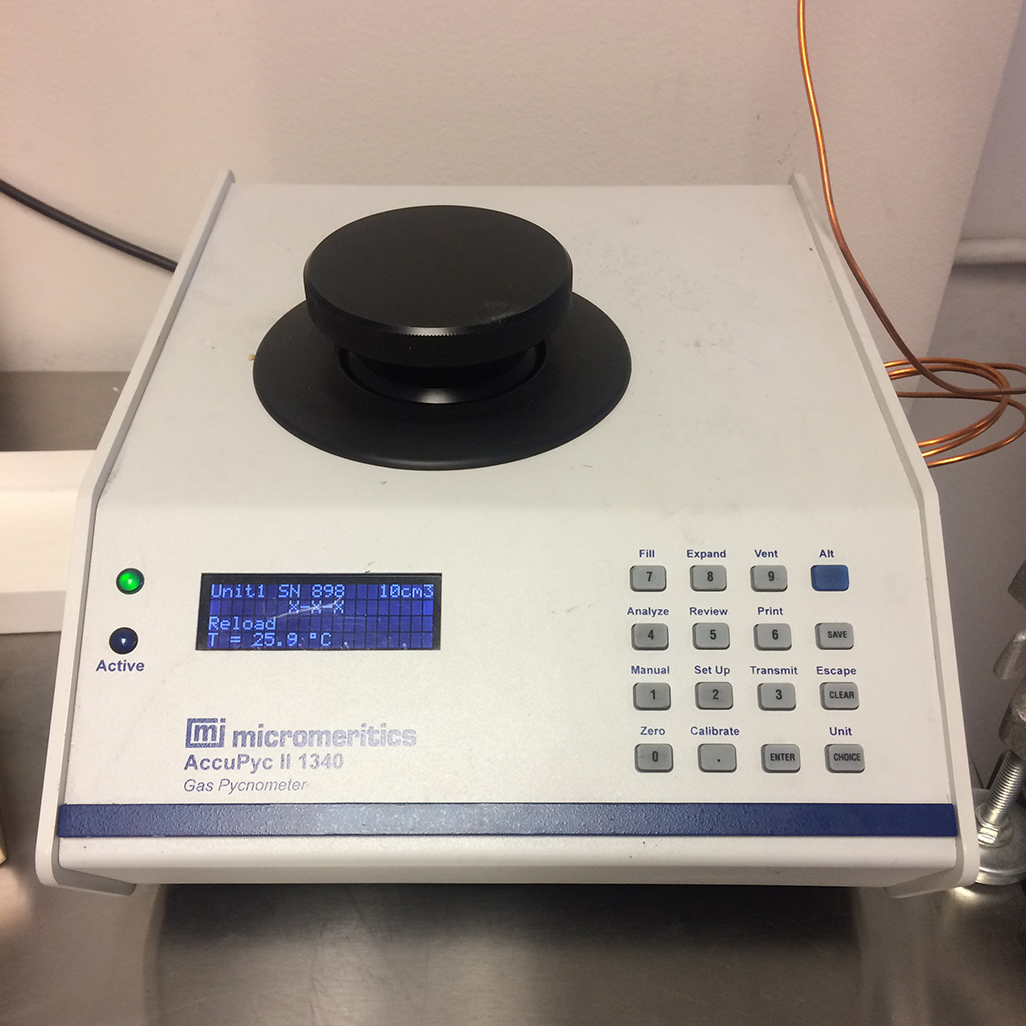

Micrometrics AccuPyc II 1340 Pycnometer

MTS

BET Surface Area and Porosity Analysis

SALD 2300 Particle Size Analysis

Allied Metal Sample Saw

Sample Microscope

Magnetic Sensitivity

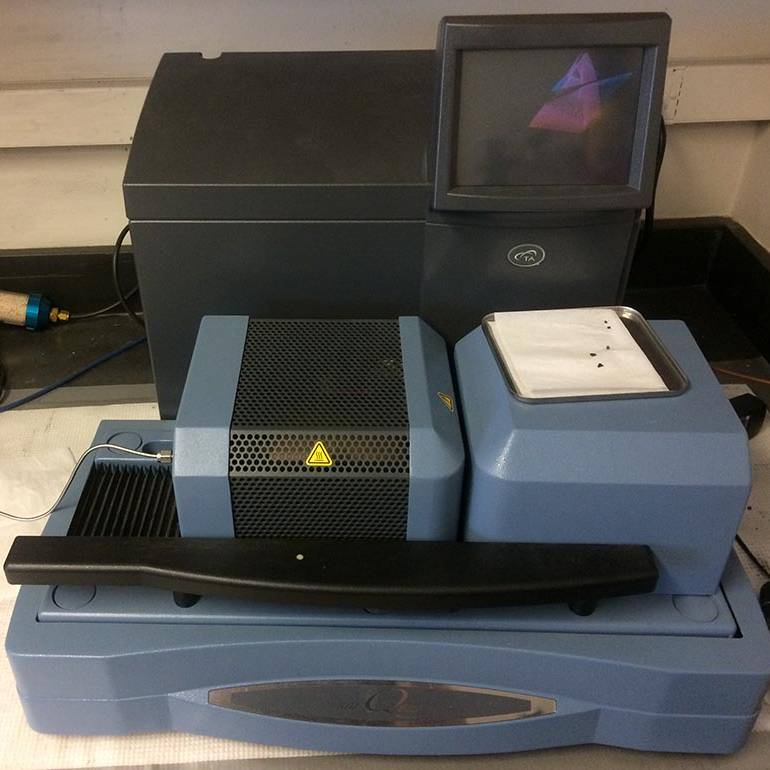

SDT Q600 TA TGA-DSC

Part Production

SLM 125

SLM 280

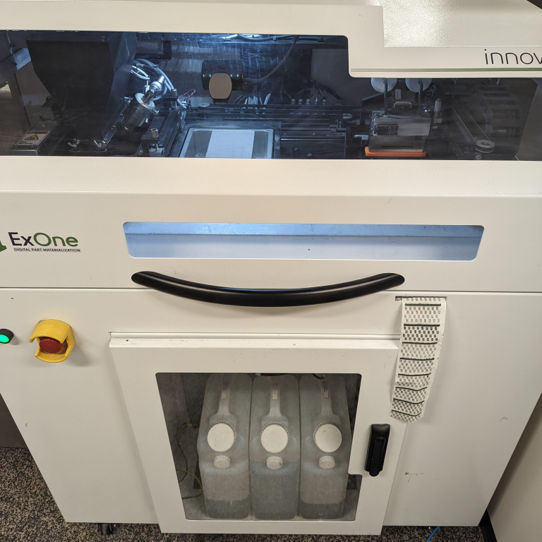

ExOne Innovent+

Part Production Method of Production

| SLM 125 | Laser Powder Bed Fusion |

| SLM 280 | Laser Powder Bed Fusion |

| ExOne Innovent+ | Binder Jet |

| Prussa i3 MK3S | FDM |

| CIP | CIP |

| Die Press | CIP |

Processing equipment

| High vacuum arc melting furnace | |

| High temperature and high vacuum sintering furnace | |

| Centorr high vacuum/inert gas hot-press (2000oC) | |

| Vertical Quenching Furnace | |

| Various heat treating furnaces and ovens | |

| Rotary evaporator, for drying wet milled powders | |

| Spray Dryer | |

| Leaching System | |

| Laminate press |

Analytical instruments

| Particle characterization equipment; Flowability, BET, Tap Density, Apparent Density, Particle Size Analyzer |

| Dilatometer |

| High temperature scanning differential calorimeter |

| Scanning electron microscope |

| Scanning TEM (JEOL 2000 FX II) |

| X-ray diffraction unit (D5000 Siemens) |

| Inductively coupled plasma spectrometer (Perkin-Elmer) |

| Electron microprobe |

| Confocal microscopy unit # Mechanical Testing |

| Computer controlled Instron tester with controlled-atmosphere furnace |

| Hardness testers (Vickers micro and macro-hardness tester, and Digital Rockwell tester) |

| LECO TCH 600 (Oxygen, Nitrogen, Hydrogen Analysis) |

| LECO C/S 2300 (Carbon, Sulfur Analysis) |

| Fatigue testing facility |

| Pycnometer |

| Sample Polishing and Mounting System |

| Metal Sample Saw |