Making Wrought-like Ti-6Al-4V via a Powder Metallurgy Method

We have developed a new powder metallurgy process called Hydrogen Sintering and Phase Transformation (HSPT) for making Ti-6Al-4V with wrought-like microstructure and mechanical properties since 2012. HSPT is multi-step pressureless sintering process, in which Ti hydride or partially hydrogenated Ti powder is blended with master-alloy or elemental alloying element powders and sintered under a dynamically controlled hydrogen atmosphere. After sintering, residual hydrogen is removed by annealing under vacuum or inert gas. HSPT takes advantage of the phase transformations in the (Ti-alloy)-H alloy systems to simultaneously refine the microstructure during the thermal cycle. A detailed description of the HSPT processing steps as well as an improved (Ti-6Al-4V)-H phase diagram and descriptions of the underlying mechanisms for microstructural refinement are available in references.

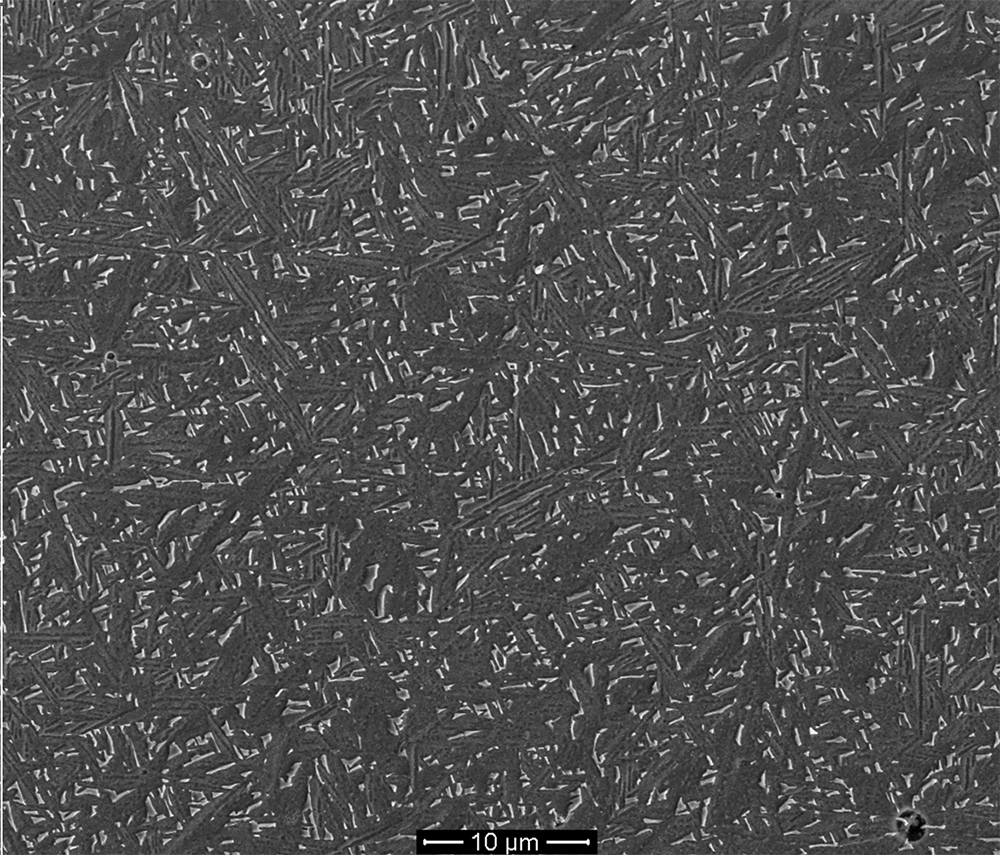

An SEM micrograph of the as-sintered microstructure produced via HSPT is showed above. In contrast with other Ti PM processing technologies, the HSPT process produces an ultrafine grain (UFG) microstructure with α colonies measuring several microns across and individual α grains measuring several microns long with submicron widths. Additionally, while traditional β-phase sintering produces a coarse lamellar α/β microstructure, the β phase in the HSPT material is finely divided throughout the microstructure. This is a key feature of the HSPT microstructure, as this allows for subsequent pressureless heat treatment steps to produce very fine wrought-like microstructures without mechanical working. By utilizing simple heat treatments on the as-sintered material, very fine wrought-like bi-modal and globularized/equiaxed microstructures are possible. It has been proposed that the very fine morphology of the as-sintered HSPT microstructure allows for the formation of globularized α grains without recrystallization.

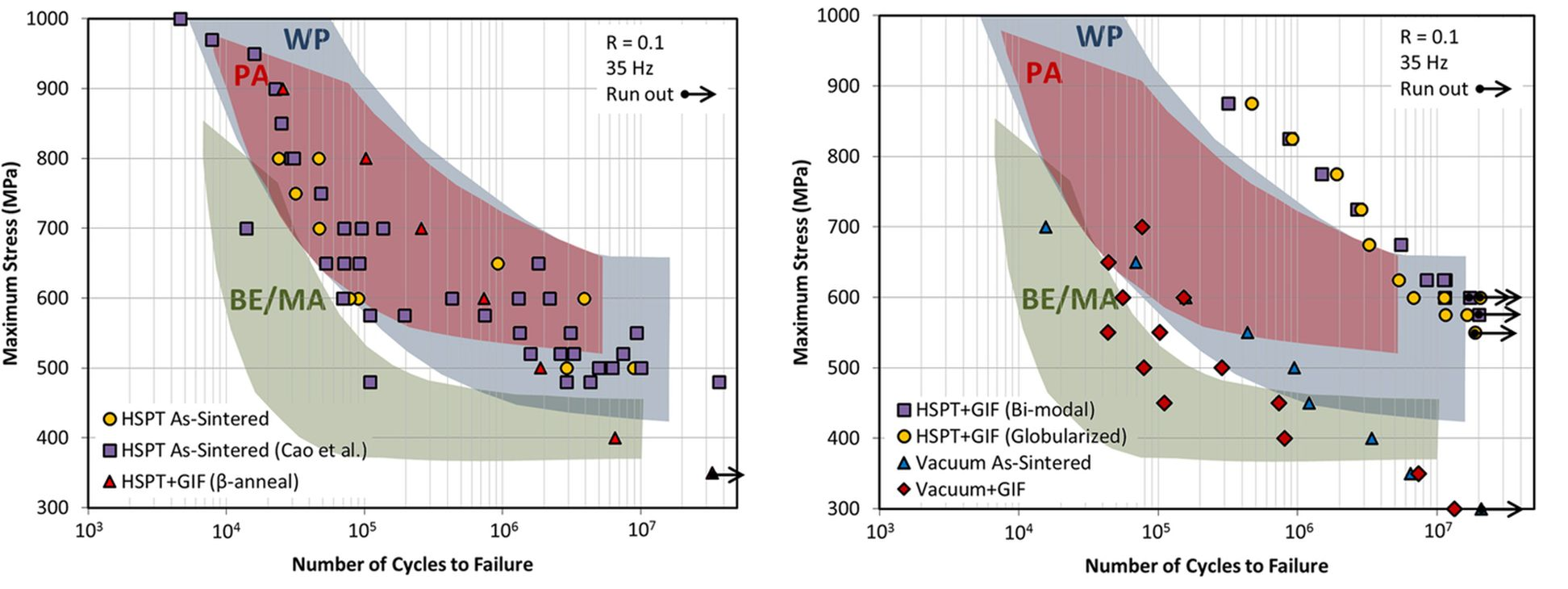

Owing to the microstructures, HSPT Ti-6Al-4V has been shown to have wrought-like mechanical properties as well. As-sintered UFG HSPT Ti-6Al-4V typically has strength exceeding 1 GPa and ductility exceeding 15 %EL. The properties may be application-tailored via simple heat treatments to increase the ductility beyond 20 %EL or strength exceeding 1100 MPa. Additionally, HSPT has been shown to have fatigue properties competitive with wrought Ti-6Al-4V.

The HSPT process has been specifically developed as a low-cost process to produce high performance Ti alloys with wrought-like microstructures and mechanical properties. As such, this research has been focused on employing commercially-viable low-cost PM processing, including:

- Low-cost blended elemental/master-alloy powder

- Conventional cold compaction and pressureless sintering (“press and sinter”)

- Only low-cost and near-net-shape compatible processing steps (no TMP such as forging, extruding, etc.)

References:

Zak Fang et al., Powder metallurgy methods for the production of fine and ultrafine grain Ti and Ti alloys, US patent 9,816,157 B2

Zak Fang et al., Hydrogen Sintering of Titanium to Produce High Density Fine Grain Titanium Alloys, Advanced Engineering Materials, 14 (2012): 383-387.

Pei Sun et al., An Experimental Study of the (Ti-6Al-4V)-xH Phase Diagram using in situ Synchrotron XRD and TGA/DSC Techniques, Acta Materialia 84(2015):29-41.

Pei Sun, et al., Phase Transformations and Formation of Ultra-fine Microstructure during Hydrogen Sintering and Phase Transformation (HSPT) Processing of Ti-6Al-4V, Metallurgical and Materials Transactions A, 46(2015):5546-5560.

James Paramore et al., A powder metallurgy method for manufacturing Ti-6Al-4V with wrought-like microstructures and mechanical properties via hydrogen sintering and phase transformation (HSPT), Scripta Materialia, 107(2015): 103-106.

James Paramore et al., Hydrogen-enable Microstructure and Fatigue Strength Engineering of Titanium Alloys, Scientific Reports, 7(2017):41444.

Matthew K. Dustan et al., The effects of microstructure and porosity on the competing fatigue failure mechanisms in powder metallurgy Ti-6Al-4V, International Journal of Fatigue, 116(2018): 584-591