HAMR Process for Titanium Production

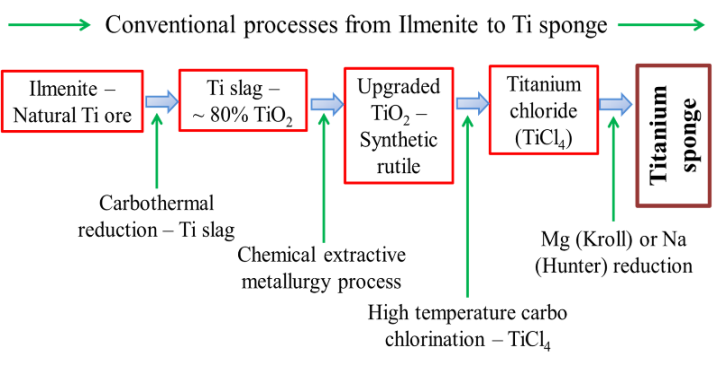

Reducing the weight of vehicles through the use of lightweight metals in place of steel is important for reducing energy consumption and emissions in the transportation sector. Unfortunately, the production of light metals is expensive and energy intensive, which is associated with the difficulty in removing oxygen from the ore, and the subsequent propensity of purified Ti metal to rapidly pick up oxygen and other impurities. In the standard Kroll process, these challenges are addressed by converting Ti ore (an oxide) into TiCl4, and then reducing the chloride to Ti metal with Mg. This technology is both capital- and energy-intensive, as the Ti metal coming out of the reduction step must be held for over a week under a high temperature vacuum distillation, and the regeneration of Mg from the MgCl2 by-product is also energy-intensive. The image below shows the conventional processes from Ilmenite to Ti sponge.

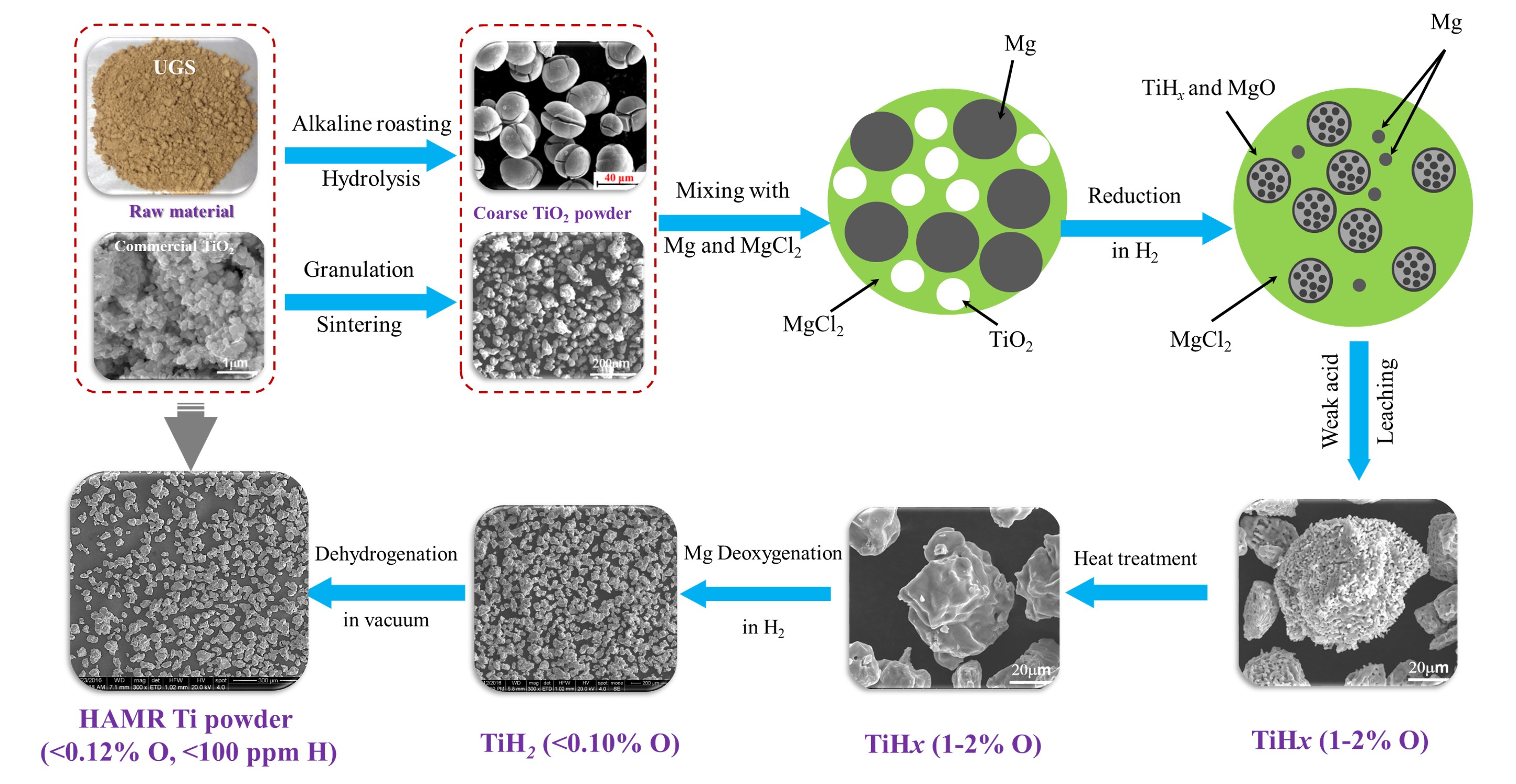

Our team has developed a novel thermochemical process to extract Ti metal from ore that substantially reduces the cost, energy consumption, and emissions of Ti metal production. It uses a new chemical process, which named “hydrogen assisted magnesiothermic reduction” (HAMR). Mg has been known to be a reducing agent for TiO2 to Ti metal. However, the equilibrium oxygen content in the Ti metal from Mg reduced TiO2 is typically higher than 1%, depending on the temperature used, which is unacceptable for industrial applications. This is because Ti-O solid solutions can be more stable than MgO. In order to further reduce the oxygen content in Ti, we discovered that Ti-O can be destabilized using hydrogen, making it possible to turn the reduction of TiO2 with Mg from thermodynamically impossible to thermodynamically favored. This allows TiO2 to be reduced and deoxygenated directly by Mg to form TiH2, with low oxygen levels that can meet the needs of the industry. TiH2 can be further processed to Ti metal through industry standard approaches. We also developed a two-step technique, which is designed to overcome kinetic barriers and engineering issues. The first step of this technique is the reduction that converts TiO2 to Ti-O solid solutions. The second step is the deoxygenation that refines Ti-O solid solutions to Ti metal with ultra-low oxygen content. The final powder contains a range of particle sizes and shapes, and is suitable for subsequent sintering or other powder applications. The detailed steps of HAMR process are illustrated in the following image.

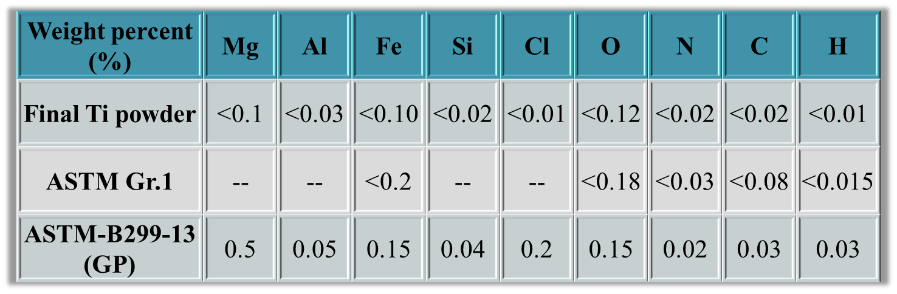

We can now produce Ti powder at a pilot scale. We produced and tested the purity of the powder against the industry standard for general purpose Ti sponge (ASTM B299-13). The typical composition of the powder is listed in the following table. The HAMR Ti powder consistently meets the purity requirements defined by the industry standard and our team has developed a reliable recipe for pilot scale production of HAMR Ti powder.

A detailed energy-economic analysis and a full process simulation were performed to estimate the energy consumption, emissions, and cost at mass production. The modeling effort included the feed materials, reaction conditions (temperature and pressure), and side processes (pretreatment of the feed materials and post-treatment of the products). The result indicated HAMR process is >50% less energy intensive and generates >30% less emissions than the Kroll process, even after accounting for an additional purification step of the TiO2 feed prior to the HAMR process. The bulk of the energy and emissions savings comes through eliminating the need to chlorinate TiO2 to make TiCl4, and vacuum distillation after the reduction of TiCl4.

This is a promising technology that has the potential to drastically alter the Ti market and increase the range of applications for high performance, lightweight Ti parts.

References:

Zak Fang et al., Methods of producing a titanium product, US Patent App. 14/935,245

Zak Fang et al., Molten salt de-oxygenation of metal powders, US Patent App. 15/314,464

Ying Zhang et al., Methods of deoxygenating metals having oxygen dissolved therein in a solid solution, US Patent 9,669,464

Ying Zhang et al., Hydrogen assisted magnesiothermic reduction of TiO2, Chemical Engineering Journal 2017, 308, 299-310.

Ying Zhang et al., A novel chemical pathway for energy efficient production of Ti metal from upgraded titanium slag, Chemical Engineering Journal 2016, 286, 517-527

Ying Zhang et al., Thermodynamic destabilization of Ti-O solid solution by H2 and de-oxygenation of Ti using Mg, Journal of the American Chemical Society, 2016, 138, 6916-6919.

Yang Xia et al. The effect of molten salt on oxygen removal from titanium and its alloys using calcium, Journal of Materials Science 2017, 52 (7), 4120-4128

Yang Xia et al. Hydrogen Assisted Magnesiothermic Reduction (HAMR) of Commercial TiO2 to Produce Titanium Powder with Controlled Morphology and Particle Size, Materials transactions 2017, 58 (3), 355-360

Yang Xia et al. Hydrogen enhanced thermodynamic properties and kinetics of calciothermic deoxygenation of titanium-oxygen solid solutions 2018, 43, 11939-11951