Thermal Energy Storage

Metal Hydrides for Thermal Energy Storage

EXCITING THERMAL BATTERY NEWS!

Funded through a major grant by ARPA-E of DOE, we are currently working to develop an exciting and novel technology - metal hydride thermal batteries (MHTB). This project seeks to demonstrate the viable application of metal hydrides for heating and cooling HVAC systems based on the reversible reactions of these materials. The thermal battery HVAC systems are to be used initially for electric vehicles, but have far reaching potential in other areas, as well. By using a thermal battery to provide heating and cooling to the cabin of an electric automobile, the driving range per electric charge will be significantly extended, and will therefore improve their practicality.

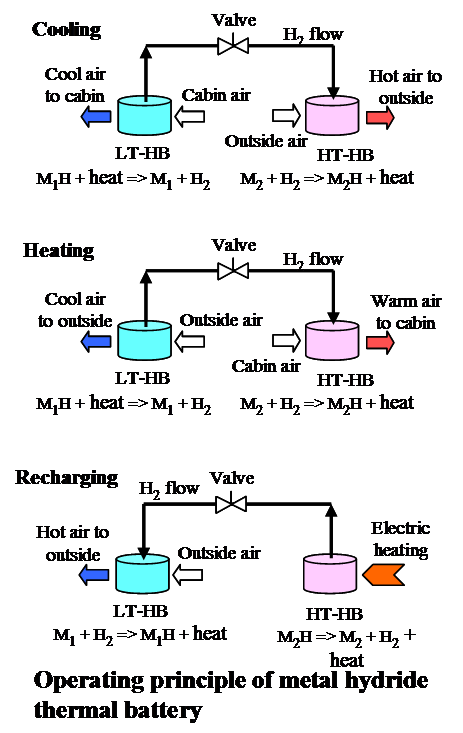

Reversible hydrogenation and dehydrogenation reactions of metal hydrides are typically characterized by the cyclic absorption and release of heat associated with the formation enthalpy of the metal to hydrogen atomic bonds. Two metal hydride materials with sufficient energy density and adequate thermodynamic and kinetic properties can be coupled together and packaged in an innovative system, designed to work seamlessly and provide both heating and cooling as one unit. The operating principle is illustrated in the figure, where LT-HB and HT-HB denote the low temperature hydride bed and high temperature hydride bed, respectively. A team of material chemists, metallurgical engineers, thermal mechanical engineers, and automotive engineers are working together to tackle the material and design engineering challenges inherent in such a ground breaking project.

Two major research thrusts are as follows:

Two major research thrusts are as follows:

-

Synthesis, characterization, and cyclic testing of the new metal hydride materials.

This effort will demonstrate the thermal battery behavior via long term cycling for more than 5000 cycles. It involves the synthesis of carefully selected and matched pairs of metal hydride materials, characterization of their physical and chemical properties, and tests of their capacity to perform well over an extended period of time. -

Engineering design, modeling, optimization, and laboratory testing of prototypes.

This thrust will integrate the hydride thermal battery into a functional HVAC system designed specifically for an electric vehicle cabin, and will involve engineering design, modeling, maximization of efficiency, fabrication, short cycle testing, long cycle testing, and validation of the model systems.